Authors of the photos: OCEAN, DAN-FENDER

Mooring fenders, commonly referred to as bumpers, are indispensable in protecting a vessel’s hull during docking. They absorb the force of impact when a ship comes into contact with a pier or another vessel, particularly during towing operations. Typically made from PVC material, these fenders are placed along the sides of the ship just before docking, serving as a buffer to absorb collision energy. For example, Ocean uses Plastisol PVC material to produce all of its fenders, which is highly valued for its properties, including:

-

Chemical Resistance: It remains inert when exposed to a wide range of chemicals and petroleum products.

-

Elasticity: The material’s flexibility allows it to absorb substantial impact without damage.

-

Energy Dissipation: Fenders are designed to absorb and distribute the energy from collisions effectively.

-

Mechanical Strength: They resist deformation even under heavy loads.

-

Environmental Durability: These fenders can withstand harsh environmental conditions, such as extreme temperatures, UV radiation, and prolonged exposure to seawater.

Choosing the Right Mooring Fenders

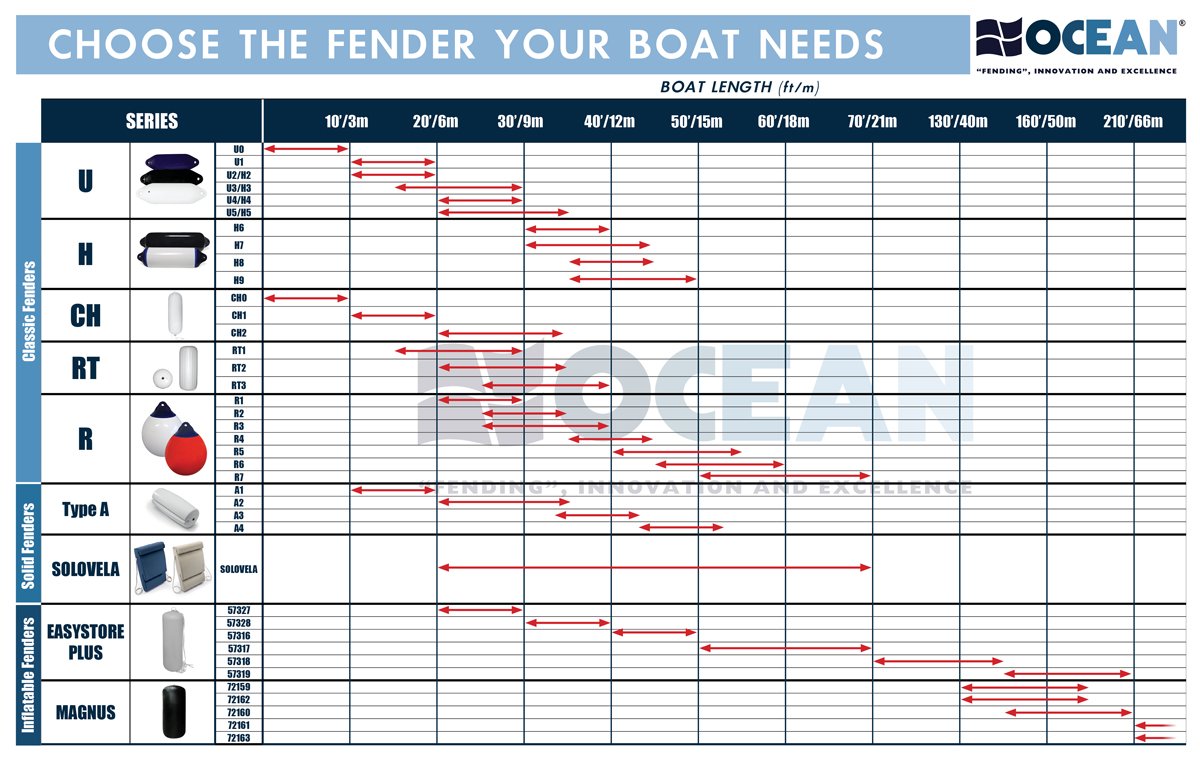

Selecting the appropriate mooring fenders depends largely on the design of the vessel and specific mooring conditions. Though there are no rigid rules, here are some general recommendations:

-

Use one fender for every 2.5 meters of the vessel’s length, with at least three fenders per side.

-

Most vessels should have between 6 to 8 fenders.

-

To determine the appropriate fender diameter, apply the formula: 2.5 cm per 1.2 meters of vessel length. For instance, a 30-foot boat would require a fender with a diameter of around 20.8 cm.

-

The fender’s length should be approximately two-thirds of the vessel’s freeboard height.

-

For inflatable fenders, maintain a pressure of 0.15-0.2 atmospheres (kg/cm²), and check the pressure once or twice a year.

Understanding the Categories of Mooring Fenders

Mooring fenders are categorized by their application and their position on the vessel.

Application-Based Categories:

-

Temporary Fenders: These are used on standard vessels, attached just before docking and removed afterward.

-

Permanent Fenders: Typically found on icebreakers and tugboats, these fenders are permanently installed for continuous protection.

Positioning-Based Categories:

-

Floating Fenders: These buoy-like fenders are connected by rigging chains and float on the water’s surface, making them ideal for larger vessels due to their bulk and weight.

-

Handing Fenders: Also known as bow, side and stern fenders, these are used on smaller vessels. They can be raised or lowered easily, without the need for winches or pulleys, and are suspended along the vessel’s sides using ropes or chains during docking.

Types of Hanging Fenders:

- Bow Fenders: These are hollow, rubber cylinders shaped like a boomerang, permanently installed at the bow to protect this vulnerable part of the vessel.

Example – OCEAN Bow Fenders

- Cylindrical Side Fenders: Installed on both sides of the ship, these fenders can be adjusted in height or removed as needed.

Example – OCEAN Fenders H SERIES, OCEAN Fenders U SERIES, OCEAN Fenders CH SERIES, OCEAN Fenders RT SERIES,

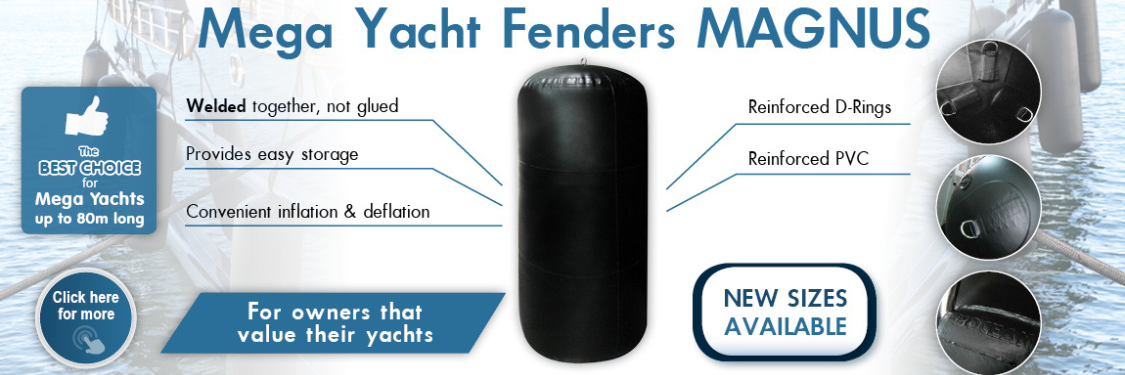

OCEAN Mega Yacht Fenders MAGNUS SERIES, OCEAN Mega Yacht Fenders EASYSTORES PLUS SERIES

- Round stern or side fenders: These are installed on the stern or swim platform and can also be mounted along the sides, closer to the bow of the vessel. These fenders can be adjusted in height and removed as needed. They provide protection during stern-to-dock mooring.

Example – OCEAN Buoys R SERIES

Operational Considerations for Using Mooring Fenders

When it comes to using inflatable fenders, they can be inflated with a standard car pump or compressor. However, it’s important to monitor the pressure, as the air inside the fender can expand under direct sunlight, potentially increasing internal pressure.

Fenders should be deployed just before the vessel enters the marina, alongside other docking preparations such as securing mooring lines and preparing to drop anchor.

On smaller vessels, fenders are usually attached to the sides using mooring cleats. For those with less experience, there is a risk of entangling the fender lines with the mooring lines during docking. To prevent this, it may be beneficial to install special hooks or clips along the sides or superstructure, which can help in the quick and efficient deployment or removal of fenders.

The “figure-eight” or “clove hitch” knots are highly recommended for securing fender lines due to their ease of tying and reliability.

Energy Absorption and Distribution in Mooring Fenders

Mooring fenders are also classified based on how they absorb and distribute impact energy:

-

Shock-Absorbing Fenders: These include elastic, pneumatic (air-filled) fenders that are designed to absorb the energy from impacts.

-

Damping Fenders: Available in gas or hydraulic variants, these fenders dissipate impact energy by compressing the gas or liquid inside.

-

Combined Fenders: Hydro-elastic and hydro-pneumatic fenders combine the features of shock-absorbing and damping fenders, offering enhanced protection through a dual-shell design.

Types of Shock-Absorbing Fenders

Pneumatic fenders come in two main designs: chambered and non-chambered.

-

Non-Chambered Fenders: These consist of a single rubber shell reinforced with metal or polymer cords. These fenders are mainly used for pleasure motor yachts and sailboats up to 60 feet in size.

-

Chambered Fenders: Also known as double-layer fenders, these feature an outer shell made of rubber-cord material and an inner sealing shell. These fenders are very often used for larger yachts and mega yachts.

Types of Damping Fenders

Hydraulic damping fenders are made from thick, durable rubber with holes that allow water to escape when compressed, effectively absorbing impact energy. These fenders are typically hung vertically and can be adjusted for positive or negative buoyancy. Gas damping fenders, on the other hand, use compressed air or gas to dissipate energy during impacts.

Combined Fenders

Hydro-elastic and hydro-pneumatic fenders incorporate air and water to absorb impact energy. The inner shell is filled with air, while the space between the shells contains water that is displaced upon impact. This design makes them compact and suitable for a range of vessel sizes.

Modern Mooring Fenders

Modern OCEAN fenders are equipped with two D-rings on opposite ends, allowing them to be mounted either vertically with one ring or horizontally using both rings, depending on the docking scenario.